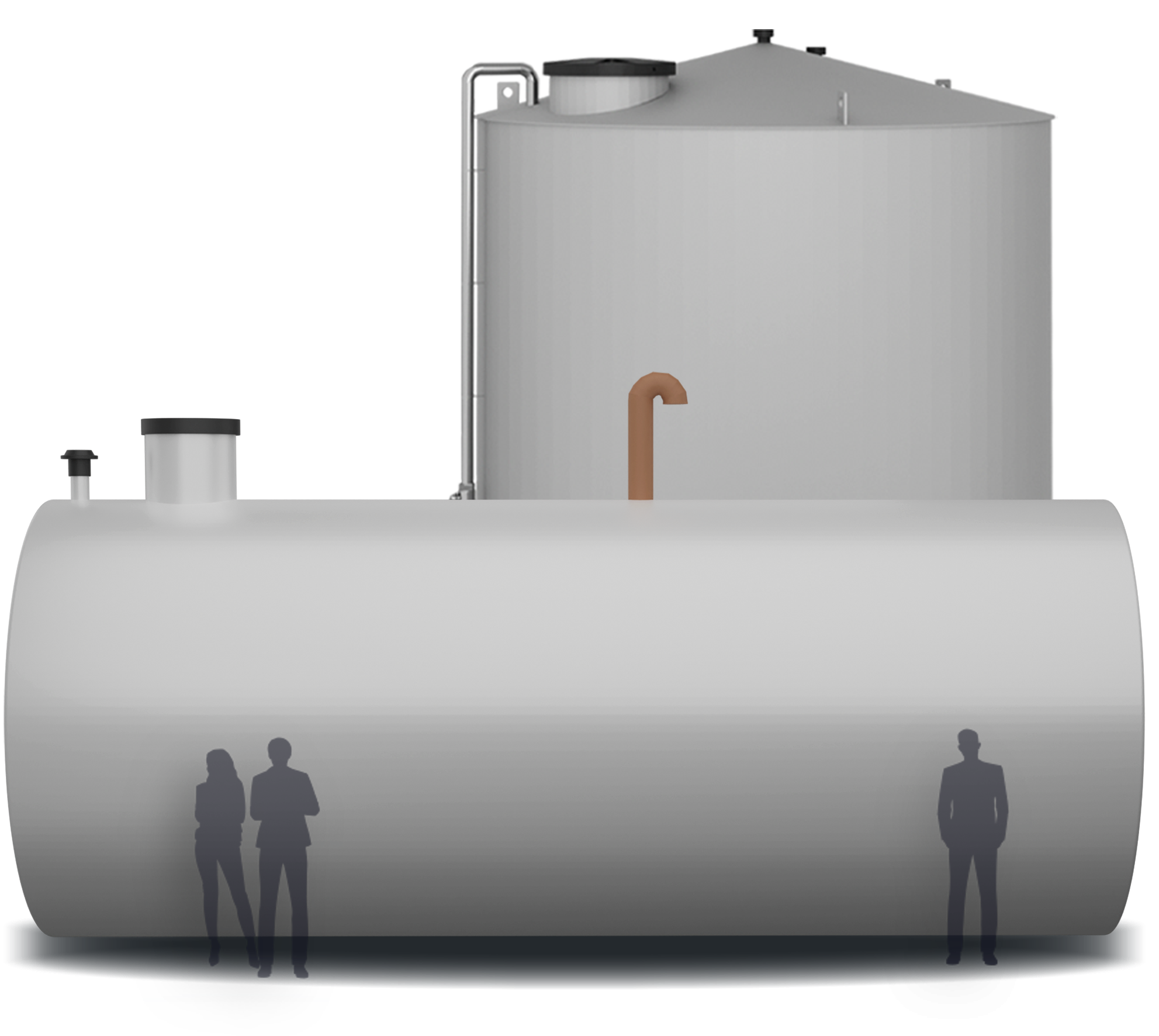

50-150 m3

Large storage

tanks

Drinking water

Biological waste water treatment, anaerobic fermenters

Methane and biogas tanks

Fire protection, firefighting tanks

Water storage basins, leachate tanks

Irrigation and agriculture, eco landfills

What solution do we offer?

Foil Pond

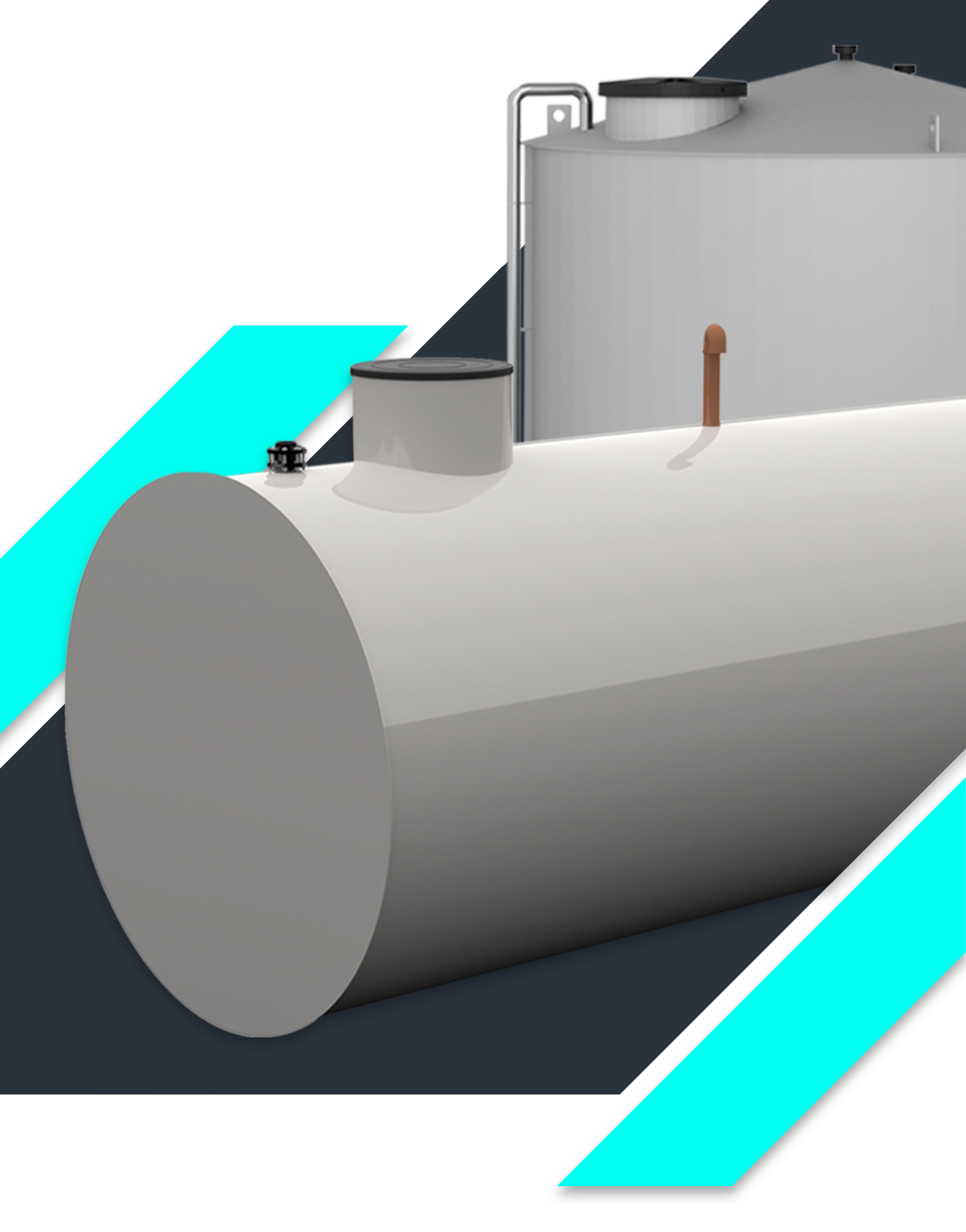

Firewater Storage Tank

Steel Tank

Durability

Vulnerable to UV exposure and weathering, shorter lifespan

Excellent, UV and corrosion-resistant, long lifespan

Prone to corrosion, requires regular maintenance

Installation

Time-consuming setup,

larger space required

Quick and easy installation with minimal preparation

Complex, heavy installation, requires a special foundation

Maintenance

Frequent liner

replacements needed

Minimal maintenance, cost-effective over the long term

Expensive maintenance due to rust and potential leaks

Safety

Open system, prone

to contamination

Outstanding, closed system, protects water from contamination

Expensive maintenance due to rust and potential leaks

Space Requirements

Larger area needed

Requires less space

Requires less space

Cost

Lower initial costs, but high maintenance needs

Cost-effective, lower

maintenance costs

High initial and

maintenance costs

Environmental Impact

Shorter lifespan, higher material consumption

Sustainable,

recyclable materials

Potential environmental burden due to corrosion

Rocky terrain? Groundwater area?

We have the solution!

With our innovative technology, you can ensure safe firewater storage anywhere – even in the toughest terrain conditions. Groundwater or rocky soil is no obstacle – our strong, stable tanks provide reliable protection for the long term. Choose the right solution and leave the challenging terrain to us!

1. Thanks to our custom solutions, installing a firewater storage tank is no problem, even in groundwater areas.

2. For rocky terrain, choose our self-supporting solutions

For more information, get in touch with our expert engineers!

Grünwald

Eco-composit:

The Future of Tank Technology

ESG Implementation – Directly from the Manufacturer

Eco-Composit is not just an ordinary high-density polyethylene formula; it is a pinnacle of modern industrial and environmental protection technology. Eco-Composit tanks were developed to meet the challenges of the industrial and environmental sectors, where durability, flexibility, and sustainability are essential. This formula combines innovative materials and technological solutions that ensure the product’s excellence and market-leading position in the long term.

- Impact resistance: High – resistant to low temperatures

- Mechanical strength: Medium – high flexibility and elongation

- Wear resistance: High – wear-resistant, long lifespan

- Flexibility: High

- Fatigue resistance: Medium – suitable for long-term use

- Thermal conductivity: Low – good thermal insulation properties

Why is Evo-Composit the future?

Eco-Composit is a pioneering technology that incorporates the most advanced materials and technical solutions. It not only enhances the durability of the tanks but also optimizes their environmental impact. Through the use of recycled materials, UV resistance, and chemical resistance, Eco-Composit tanks meet the expectations of both the present and the future.

Choose Eco-Composit tanks and step into the world of sustainable, innovative storage solutions!

Water absorption

Very low – Virtually does not absorb water

Liquid permeability

Very low – Does not let liquids through

Chemical resistance

Excellent – Particularly resistant to acids and alkalines

Corrosion resistance

Excellent – Does not corrode

Weldability

Excellent – Easily weldable

Recyclability

Excellent

For more information, get in touch with us!

Grünwald ESG

Environmental, Social and Governance

Eco-Composit has become the material of choice across industries not just because of its superior performance but because of its long-term sustainability. Companies adopting Eco-Composit are aligning themselves with ESG principles, enhancing their environmental performance, and contributing to a circular economy. This material is future-proof, ensuring that businesses are not only prepared for today’s challenges but for the challenges of tomorrow.

The engineers who developed Eco-Composit have created more than a material; they’ve created a movement. Eco-Composit reflects the best of European and American engineering, innovation, and sustainability. It represents 15 years of hard work, dedication, and experience, culminating in a formula that is shaping the future of tank manufacturing and environmental responsibility.

Continue to the full story

The Evolution of a Future-Ready, Circular Economy Solution: The Story of Eco-Composit

It all started more than 20 years ago when a group of forward-thinking students and engineers from several European countries traveled to the United States. These engineers and students, hailing from Germany, Hungary, Romania, Italy, and the UK, embarked on an academic and professional journey to one of the world’s most innovation-driven nations. The purpose was clear: to learn, absorb, and bring back the cutting-edge knowledge and revolutionary thinking that would pave the way for future industrial advancements back home.

The United States, with its unparalleled focus on innovation and sustainability, became a fertile ground for these students and engineers to study the integration of technology, industry, and environmental awareness. Over the years, they witnessed remarkable innovations that emphasized the importance of sustainability, circular economy principles, and high-performance materials in the face of increasingly complex industrial challenges.

When these engineers returned to Europe, they carried with them not just technical knowledge, but a new way of thinking. They understood that the future of industrial manufacturing wasn’t just about creating stronger products; it was about creating smarter, more sustainable solutions. This idea planted the seed for what would become a 15-year journey of relentless product development, one filled with trials, prototypes, and learning.

The Path to Eco-Composit

For 15 years, these engineers honed their craft across multiple industries. They gathered expertise from designing and producing thousands of tanks, gaining hands-on experience across Europe’s most challenging environments. This journey led to the formation of an idea: a material that would be the cornerstone of the future – a formula that would combine exceptional performance with the highest sustainability standards.

This tireless research, development, and real-world application experience eventually led to the creation of Eco-Composit, a groundbreaking high-density polyethylene formula designed to withstand the most demanding industrial environments. Eco-Composit isn’t just another material; it’s the future of tank manufacturing and sustainability.

What Makes Eco-Composit Revolutionary?

The Evo-Composit formula is a food-grade certified material that meets the stringent safety requirements for industries like food and beverage. But beyond that, its properties are nothing short of extraordinary:

- Resistance to Acids and Alkalines: Eco-Composit tanks are impervious to the most aggressive chemicals, making them ideal for environments where strong acids, alkalis, or hazardous waste are present.

- Total Wastewater and Contaminant Resistance: Eco-Composit is engineered to handle all types of wastewater, including the dirtiest and most corrosive substances. Whether it’s industrial sludge, agricultural run-off, or hazardous chemical waste, Eco-Composit can endure it all.

- Unmatched Durability Against Harsh Liquids: From the roughest industrial chemicals to the most unpredictable environmental fluids, Eco-Composit is built to last. It maintains its structural integrity even in the most challenging conditions, ensuring long-term reliability and safety.

The Future of Tank Manufacturing in Industrial Sectors

Eco-Composit isn’t just a material—it’s the future of tank manufacturing across multiple industries. Its versatility, durability, and resistance to extreme conditions make it an essential component in a variety of industrial applications:

- Chemical Industry: In facilities dealing with aggressive acids, alkalis, solvents, and other hazardous chemicals, Eco-Composit tanks ensure safe storage and longevity.

- Food and Beverage: Certified for food-grade safety, Eco-Composit tanks are ideal for storing ingredients, liquids, and waste products, providing peace of mind with their hygienic, non-reactive properties.

- Pharmaceutical Industry: For storage and transport of sensitive chemicals, clean water, or pharmaceutical waste, Eco-Composit offers unparalleled reliability in maintaining the purity and integrity of substances.

- Agriculture: Eco-Composit tanks are used for storing fertilizers, pesticides, irrigation water, and even biogas, where durability and resistance to chemicals are key.

- Mining: In environments filled with abrasive materials, chemicals, and heavy usage, Eco-Composit tanks withstand wear and tear while ensuring maximum safety and efficiency.

The Key to Environmental Sustainability

What sets Eco-Composit apart from other materials is its full alignment with the principles of the circular economy. The engineers behind Eco-Composit didn’t just set out to create a durable material; they wanted to ensure it aligned with the highest sustainability standards, enabling businesses to boost their ESG ratings (Environmental, Social, Governance).

Eco-Composit supports a circular economy in the following ways:

- Recyclability: At the end of its long life cycle, Eco-Composit tanks can be fully recycled, reintroduced into production, and turned into new tanks, thus minimizing waste and reducing the reliance on virgin materials.

- Reduced Carbon Footprint: Eco-Composit’s lightweight nature reduces transportation costs and emissions, helping industries reduce their environmental impact. Its durability means fewer replacements are needed, reducing the overall carbon footprint.

- Water Management Solutions: In industries ranging from wastewater treatment to environmental remediation, Eco-Composit helps manage water resources more efficiently. It is a key material for storing, treating, and recycling water, ensuring sustainable water management practices.

Applications in Environmental Technology

Eco-Composit is revolutionizing the field of environmental technology with its unparalleled resilience and versatility. Its role extends across multiple environmental sectors:

- Wastewater Treatment: Eco-Composit tanks are integral to wastewater treatment plants, where they store and treat water contaminated with chemicals, sewage, or industrial waste. Their resistance to harsh chemicals ensures a longer lifespan and reduced need for replacements.

- Biogas Production: Eco-Composit is the material of choice for anaerobic digesters and biogas storage tanks, where corrosive gases and biological waste are processed and stored. Its non-reactive surface ensures efficient biogas production with minimal risk of contamination.

- Leachate Storage: In eco-landfills and waste treatment facilities, Eco-Composit tanks are critical for collecting and storing leachate, the liquid that percolates through waste, which often contains harmful chemicals. Eco-Composit prevents leaks and ensures environmental safety.

- Firefighting Water Storage: Eco-Composit tanks are also essential for storing firefighting water in areas prone to wildfires, where reliable and immediate water supply is critical for containing and extinguishing fires.

A Formula That Transforms Industries

Eco-Composit has become the material of choice across industries not just because of its superior performance but because of its long-term sustainability. Companies adopting Eco-Composit are aligning themselves with ESG principles, enhancing their environmental performance, and contributing to a circular economy. This material is future-proof, ensuring that businesses are not only prepared for today’s challenges but for the challenges of tomorrow.

The engineers who developed Eco-Composit have created more than a material; they’ve created a movement. Eco-Composit reflects the best of European and American engineering, innovation, and sustainability. It represents 15 years of hard work, dedication, and experience, culminating in a formula that is shaping the future of tank manufacturing and environmental responsibility.

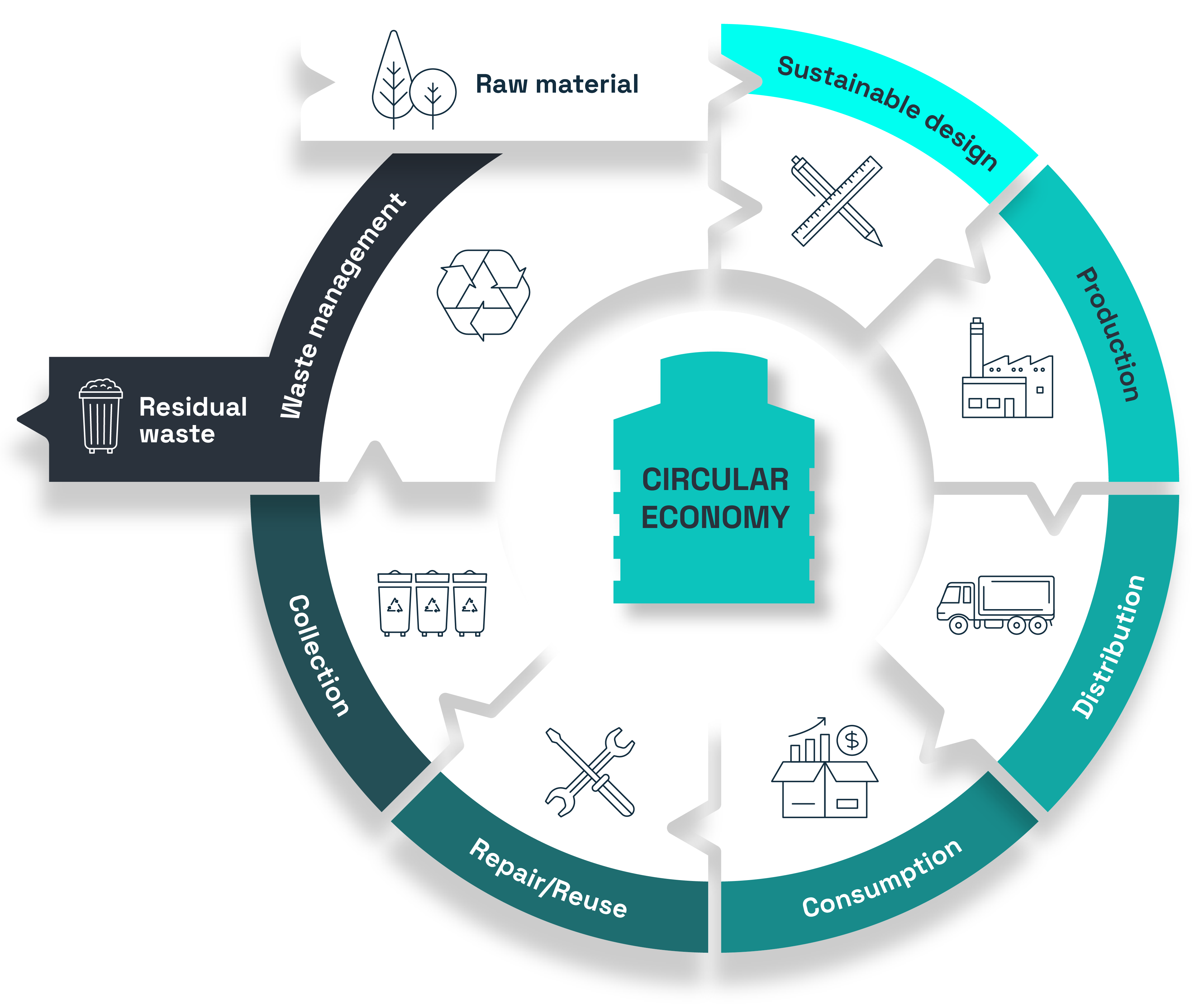

Grünwald and the Path to

a Circular Economy

1. Product design and manufacturing

Sustainable product design is part of the circular economy, resulting in more durable, repairable and recycable products, reducing the demand for new raw materials.

2. The role of consumers

Consumers can help to create a green economy by choosing sustainable products.

3. Improving waste management

Improving waste collection and recycling is important to recover valuable materials and reduce environmental impacts.

4. Supporting the market for secondary raw materials

Expanding the market for recycled materials reduces the need to extract natural resources.

5. Sector-specific measures

The EU is introducing targeted measures to promote sustainability in industries such as plastics, construction, textiles and electronics.